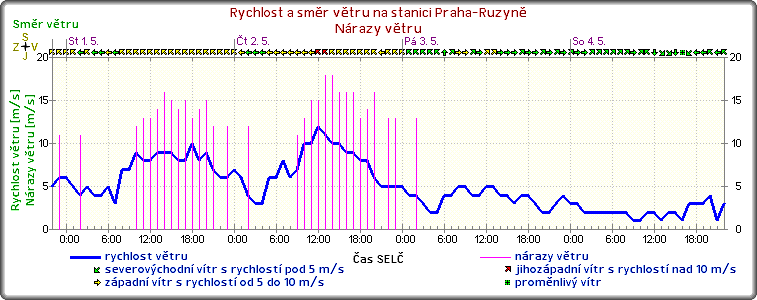

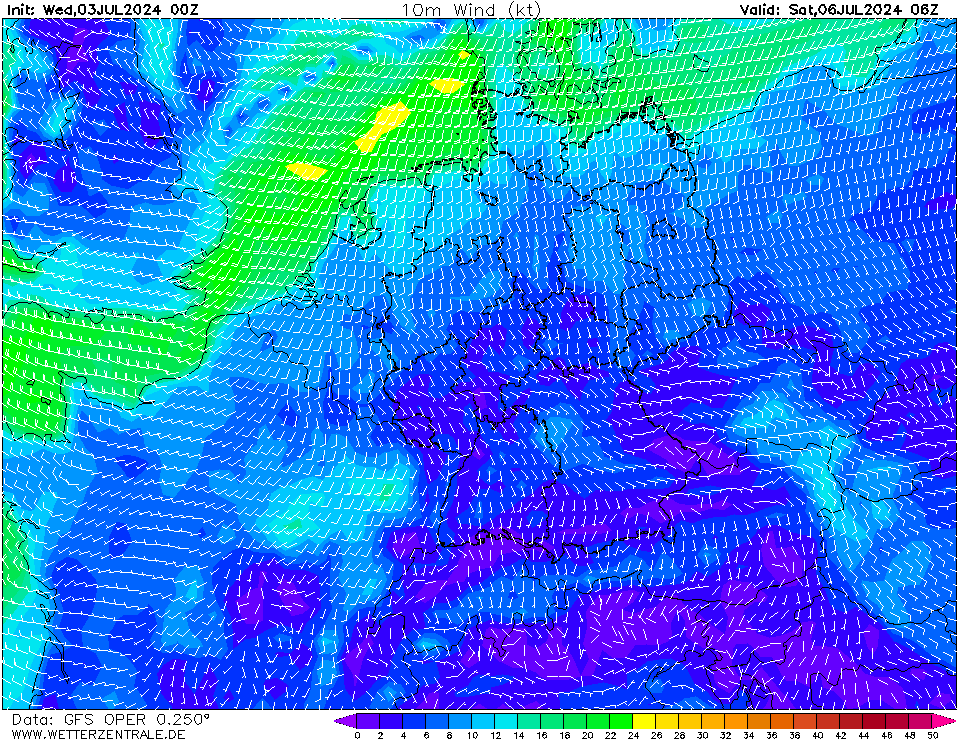

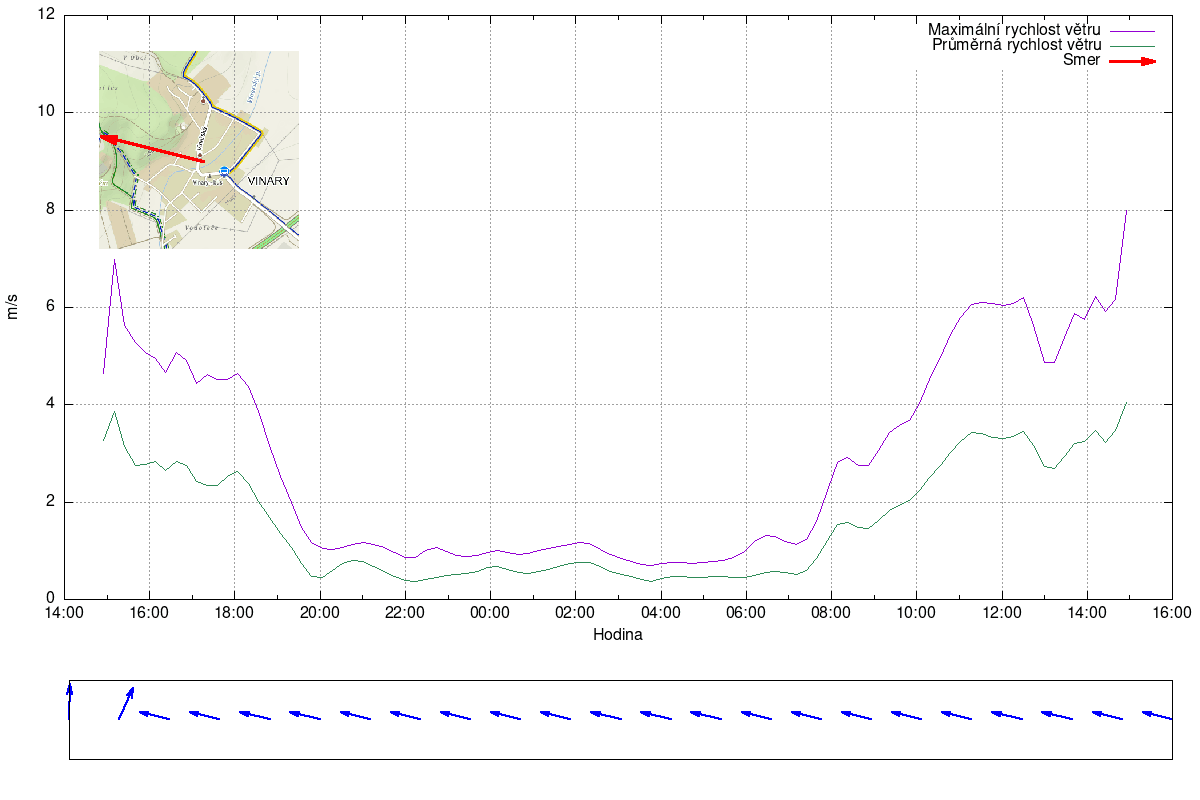

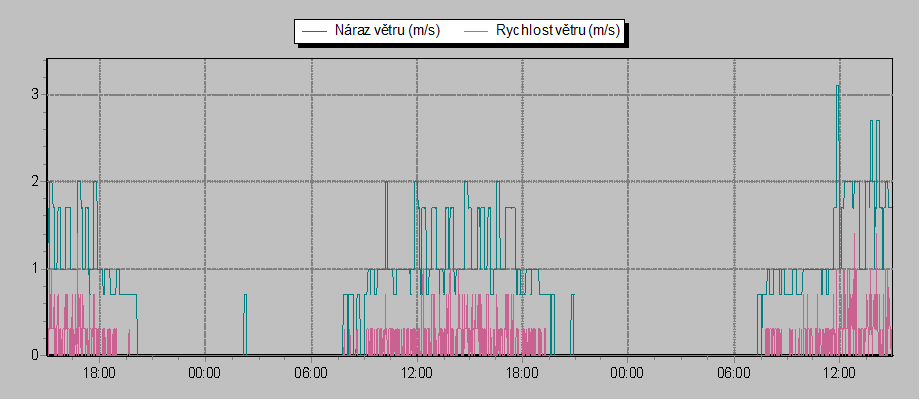

METEO AKTUALITY - AKTUÁLNÍ VÍTR: Rychlost větru v ČR v poledne dosahuje nejčastěji 5 až 10m/s, ojediněle 13m/s a to hlavně v Praze a na severozápadě Čech. (chmi.cz) | Facebook

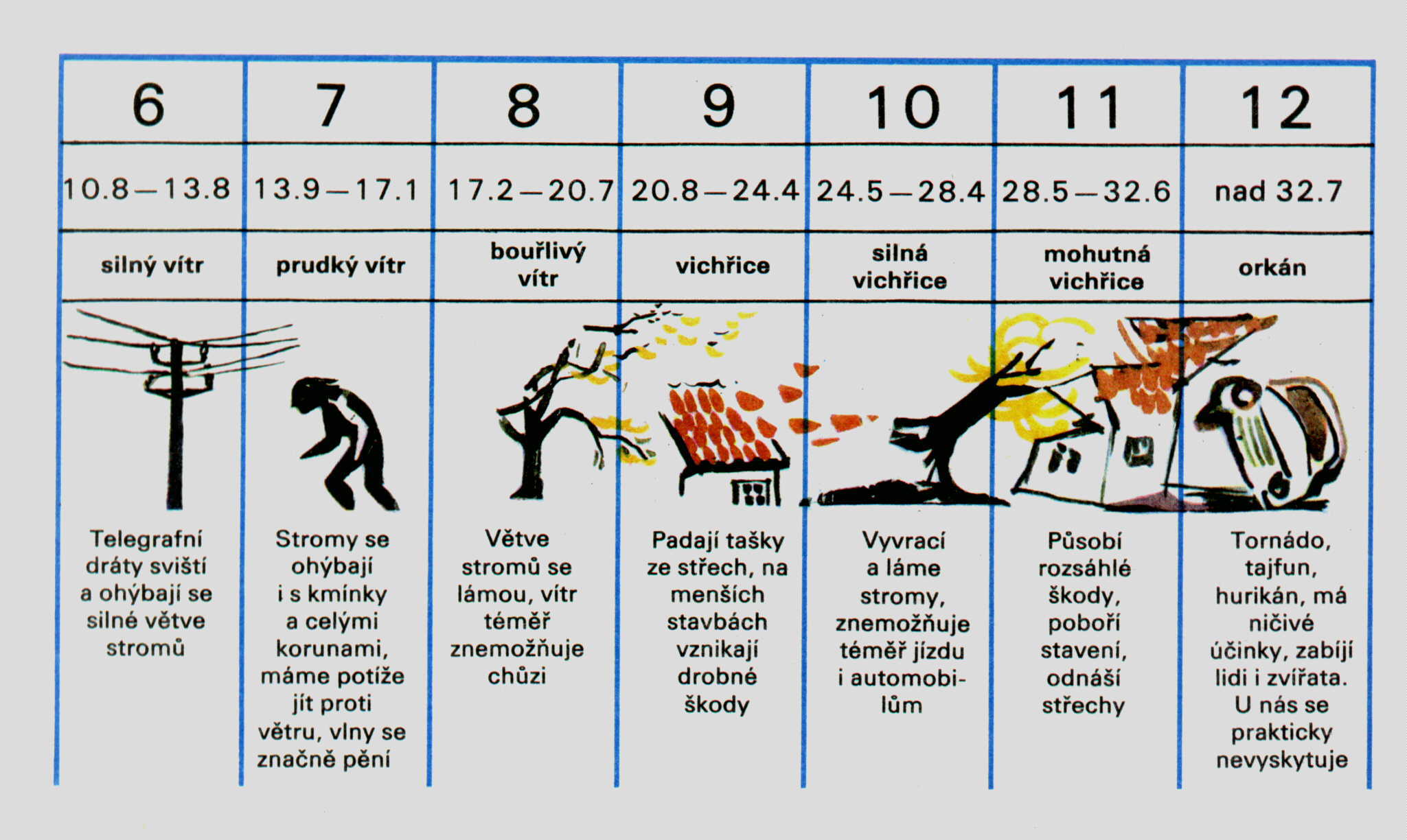

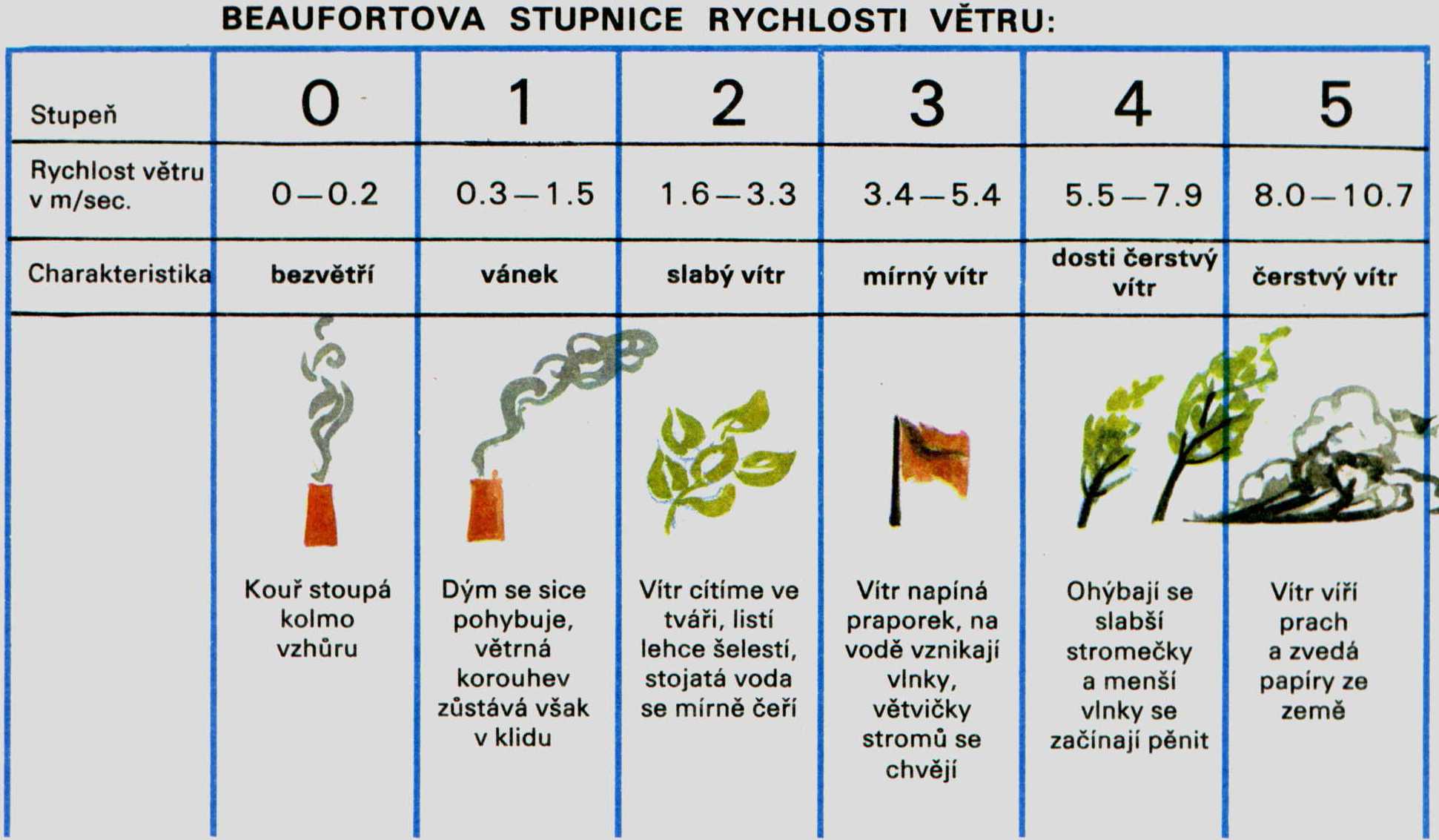

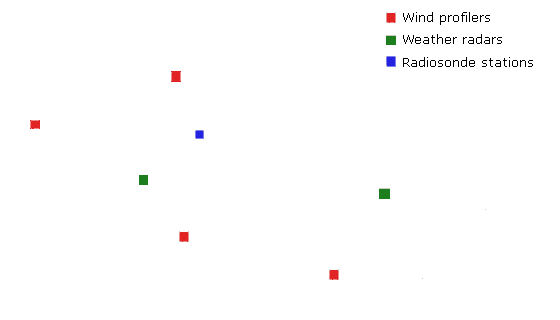

Portál ČHMÚ : Aktuální situace : Aktuální stav počasí : Česká republika : Stanice : Profesionální stanice : Mapy : Vítr